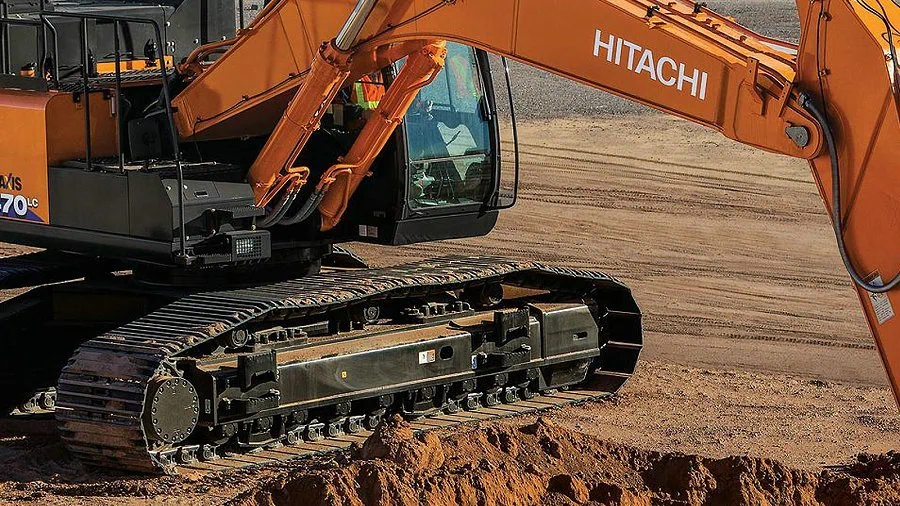

Are you seeing wear or damage on the undercarriage of your machine? If you are, you need to address it quickly. You can have an incredible repair bill and be out of operation in a heartbeat. Early warning of damage or rips can easily turn into a golden opportunity to save you a ton of time and money. It allows you to keep your machine running efficiently and effectively for years to come. Let’s look at how you can identify what is tearing up your undercarriage parts before it gets out of control.

Identifying damage in excavator undercarriage parts is crucial for preventing costly repairs and maintaining optimal performance. Regular visual inspections, listening for unusual noises, and monitoring operational performance are all effective ways to spot potential issues early. This guide provides detailed steps on how to detect damage in key undercarriage parts, including tracks, rollers, sprockets, and idlers. Stay ahead of potential issues and keep your equipment running smoothly with these practical tips.

Now, let’s dive into the key signs of damage and how to properly inspect your excavator’s undercarriage parts.

Table of Contents

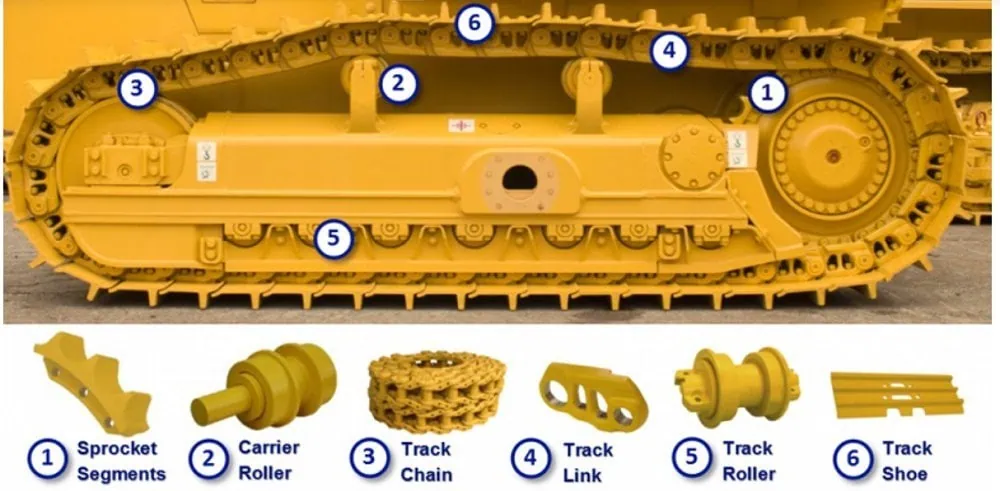

ToggleCommon Excavator Undercarriage Parts

Before we go any further in the identification process, it’s essential to understand the components of the undercarriage. The undercarriage supports the entire weight of the machine, allowing it to move efficiently and safely across rough terrains. Each part plays a crucial role in the operation of the machine. Any damage to these parts can cause a significant problem that affects your machine’s operation. Early recognition will save you from costly repairs and keep your machine rolling down the road.

Key Undercarriage Components:

| Component | Role | Damage Symptoms |

| Tracks | Provides traction and supports the weight of the excavator | Cracks, excessive wear, missing links, uneven track tension |

| Rollers | Allows the tracks to move smoothly by supporting the weight of the machine | Oval shape, worn bushings, misalignment, reduced mobility |

| Sprockets | Engages with the tracks to propel the machine | Worn teeth, cracks, misalignment, abnormal noise |

| Idlers | Maintains track tension and alignment to prevent derailment | Cracking, excessive wear, misalignment, uneven track tension |

| Track Frames | Houses the other components and provides overall support | Cracks, excessive wear, missing or damaged bolts and fasteners |

Understanding the Function of Each Component:

Tracks: Tracks are the foundation of an excavator’s mobility. Their primary purpose is to provide traction on various surfaces, enabling the machine to navigate rough and uneven terrains. When tracks are damaged, the excavator’s movement becomes hindered, affecting efficiency and safety. Cracks or excessive wear on the tracks may be the first indication that it’s time for an inspection.

Rollers: Rollers support the track system by allowing smooth movement as the machine operates. The rollers distribute the weight across the tracks and help maintain the balance. If rollers show signs of oval shapes or worn bushings, it can indicate poor performance and potentially cause the machine to move unevenly.

Sprockets: Sprockets are vital for engaging with the track links, propelling the machine forward. When the teeth of the sprockets become worn or cracked, or if there is any misalignment, the machine’s movement will be compromised, and further damage to the undercarriage can occur.

Idlers: Idlers maintain proper track tension and alignment. They play a key role in keeping the track system functional, and any cracks or misalignment will cause excessive wear and decrease the machine’s efficiency. Uneven wear in idlers can also cause derailment or improper track tension.

Track Frames: Track frames are the structural foundation that houses and supports the entire undercarriage system. When track frames are damaged or cracked, they can lead to instability in the system, causing additional wear on the other parts.

How to Identify Damage in Excavator Undercarriage Parts

Check the condition of the sprockets teeth and be sure they have not worn to the point of not maintaining proper track engagement. If there was a gh on the machine, we would typically recommend them to change sprockets, as the cost of a new set of sprockets is going to be less than replacing the bushings and pins in the track as a result of the sprockets wearing out early.

Also, make sure idlers are not bent or out of position and keep the proper tension on the track. One of the worst things you can do is let the track get too loose or too tight. This kind of maintenance is required to maximize the life of undercarriage components. With the right adjustments and maintenance, you can reduce the risk of any undercarriage issues for the first four thousand to six thousand hours of machine life.

Visual Inspection: Key Signs of Damage

Unfortunately, the undercarriage elements suffer the lion’s share of damage caused by the board pushing and tracking over uneven terrain. Point out that by doing an inspection and adjustments according to above the operator can reduce the risk of any undercarriage issues in the first four thousand to six thousand hours of machine life.

Worn or Cracked Tracks: The tracks are the most common to show the wear point. The tracks are in direct contact with the ground and can show cracks or uneven wear as they wear down.

| Track Damage Type | What to Look For | Impact |

| Cracking | Small or deep cracks on track surface | Can lead to track breakage and loss of traction |

| Missing Track Links | Sections of track links that are missing or damaged | Reduced stability and performance |

| Excessive Wear | Uneven wear or thinning of the track surface | Decreased track life and compromised traction |

Uneven Wear on Rollers: On the excavator track systems, the roller is the most overlooked wear point. Rollers allow the tracks to move in and out on the idler, as well as around the sprocket. When they wear to an oval shape or are not running straight, they will wear the flange on them. If bad enough, this can also wear into the chain on a dozer track option.

| Roller Damage Type | What to Look For | Impact |

| Oval Shape | Rollers begin to lose their circular shape | Causes uneven movement and accelerated wear |

| Worn Bushings | Signs of wear on the bushings | Reduced roller functionality, uneven track tension |

| Misalignment | Rollers are not rotating properly | Causes jerky movements and further damage |

Damaged Sprockets: The sprockets are what grab the tracks, making the tracks move to propel the machine. The teeth on the sprocket will wear down over time, and if they wear down too much, you won’t get good engagement of the track, and your machine won’t move properly.

| Sprocket Damage Type | What to Look For | Impact |

| Worn Teeth | Teeth appear thinner or chipped | Decreases track engagement, causing slippage |

| Cracks | Visible fractures in the sprocket teeth | Causes misalignment and can lead to track issues |

| Misalignment | Sprockets no longer align with the tracks properly | Leads to poor machine movement and wear |

Damaged Idlers or Track Frames: The idlers keep tension on the track. If they are damaged, this can lead the track to flop or walk side to side, causing added damage all around. If the track frames themselves receive significant damage, they can cause tracking issues in addition to undermining the structural integrity of the undercarriage.

| Idler/Track Frame Damage Type | What to Look For | Impact |

| Cracking | Visible cracks in the idler or frame | Can lead to misalignment and frame failure |

| Excessive Wear | Unusual wear patterns or loose parts | Causes track misalignment and unstable movement |

Operational Indicators: Performance-Related Signs of Damage

In addition to the visual checks mentioned, how the machine performs will also help you see there are issues with your excavator’s undercarriage. Here are some clues beyond your daily visual inspection:

Uneven Movement or Sluggish Operation: If your excavator is moving unevenly, hesitating during operation, or lacking power, this may indicate a problem with the undercarriage. Worn rollers, misaligned sprockets, or damaged tracks can contribute to these issues.

| Movement Issue | Possible Cause | Solution |

| Uneven Movement | Misaligned or worn rollers | Check and replace damaged rollers or adjust alignment |

| Sluggish Operation | Worn sprockets or damaged track frames | Replace worn sprockets and check track tension |

| Lack of Power | Damaged tracks or idlers | Inspect and replace tracks or idlers as needed |

Excessive vibration or noise: Unusual vibrations or grinding noises can be signs that internal parts (rollers, sprockets, tracks, etc.) are rubbing against each other. Ignoring these noises can lead to major damage.

| Vibration or Noise Issue | Possible Cause | Solution |

| Excessive Vibration | Worn or misaligned rollers | Realign or replace rollers |

| Grinding or Clicking Noise | Damaged sprockets or track components | Replace damaged sprockets and inspect for cracks |

Track Slippage: If your track slips as you’re operating your machine, it can be due to sprocket wear, the track being too loose, track misalignment, or all three. Any way you look at it, track slippage means less traction for your track, which reduces efficiency and will make it harder to do your job.

| Slippage Type | What to Look For | Impact |

| Track Slipping During Digging | Worn sprockets or improper track tension | Loss of traction, decreased digging efficiency |

| Track Slipping During Movement | Misaligned tracks or sprockets | Increased wear on parts and potential failure |

Popular Topics Related to Excavator Undercarriage Damage

Regular maintenance practices can significantly extend the lifespan of your undercarriage parts. Here are a few key recommendations:

| Maintenance Tip | What It Helps With | How to Implement |

| Regular Lubrication | Reduces friction and prevents wear | Use recommended lubricants and apply them regularly |

| Frequent Cleaning | Removes dirt and debris that causes damage | Clean the undercarriage after each use |

| Avoid Overloading | Prevents unnecessary stress on parts | Operate within the machine’s weight capacity |

Here are some key early signs to watch out for:

| Warning Sign | What It Means | Action to Take |

| Uneven Track Wear | Possible misalignment or poor maintenance | Inspect tracks for damage and replace parts if needed |

| Abnormal Noise or Vibration | Worn or damaged internal components | Stop operation and inspect for damaged rollers/sprockets |

| Frequent Track Slippage | Issues with sprockets or track tension | Adjust or replace sprockets, check track tension |

Several factors can cause premature wear on your undercarriage parts. Some common causes include:

| Cause | How It Affects the Undercarriage | Prevention Tip |

| Improper Terrain | Rocks, mud, and rough surfaces accelerate wear | Avoid operating in excessively rough terrain |

| Inadequate Maintenance | Lack of lubrication and cleaning leads to friction | Schedule regular maintenance and cleaning |

| Excessive Loads | Overloading strains undercarriage components | Operate within the machine’s weight limits |

Advanced Diagnostic Tools and Techniques

However, you won’t always see the wear and tear on these parts despite your best visual inspections and operational checks. If your standard methods don’t show any issues, using advanced diagnostics can help you get to that hidden damage while it’s still a minor issue rather than finding out you have an expensive problem later. Using these techniques, you can diagnose your critical wear parts before they fail. When you can spot an issue before it becomes a problem, it saves a lot of money.

Here are some of the most common and effective diagnostic tools used for detecting undercarriage damage:

| Diagnostic Tool | Function | Application |

| Ultrasonic Testing | Detects cracks and thickness changes in parts like rollers, tracks, and sprockets | Used for checking internal damage, especially in rollers, tracks, and sprockets |

| Thermal Imaging | Identifies overheating parts through temperature variation | Can detect overheating components like bearings and bushings, which may indicate wear or failure |

| Vibration Analysis | Analyzes vibration frequency to diagnose problems in undercarriage components | Helps monitor abnormal vibrations in rollers, tracks, and sprockets, signaling potential issues |

Ultrasonic Testing

An ultrasonic test is a non-destructive test method that sends sound waves into the material to detect things you can’t see visually, like internal cracks or material thickness changes. This test is particularly beneficial for parts like rollers, tracks, and sprockets where you can’t always see the damage. By sending high- frequency sound waves through the metal part, the tool can tell you if you have internal damage or wear. Using the ultrasonic test on wear parts helps you identify potential problems that could lead to parts failure down the road.

Thermal Imaging

Thermal imaging utilizes infrared cameras to show you the heat in heavy machinery parts. Heat is generally an indicator of friction or wear problems. In excavators, refrigerator, or other equipment, parts like bearings, bushings, and sprockets can overheat from lack of lubrication or because they’re not aligned and working correctly. Heating a bearing by six degrees only reduces its life by half. If anything’s hot on a piece of equipment, infrared imaging can show you where it’s coming from. This system is a quick way to flag items that are in danger of breaking, so you can maintain or repair them before they fail catastrophically.

Regular Maintenance and Repair Tips for Undercarriage Parts

Regular maintenance is crucial to ensuring the longevity of your excavator’s undercarriage. Over time, wear and tear will naturally occur, but with proper care, you can extend the lifespan of key components and avoid major repairs. Below are the most effective maintenance practices you should incorporate into your routine to ensure your machine’s undercarriage stays in top shape:

| Maintenance Practice | Purpose | Frequency |

| Track Inspection | Check for cracks, wear, and proper tension to avoid track derailment | Every 250-500 working hours |

| Roller and Sprocket Lubrication | Reduces friction and wear between parts, preventing failure | Every 100 working hours |

| Track Cleaning | Prevents dirt and debris from building up, reducing strain on parts | After every use or daily |

| Adjusting Track Tension | Ensures tracks are aligned and reduces slipping and wear | Every 100 hours of operation |

| Component Lubrication | Reduces friction and prevents part failure in rollers and sprockets | Every 100-150 working hours |

Regular track inspections should also be performed on a regular basis to check for damage. Look for track wear, cracks, and improperly tensioned tracks. Many times, you can see these issues by visually inspecting the track. In addition to visually inspecting the track, always observe the track’s straightness since a crooked or misaligned track can place extra load on other undercarriage parts, forcing them to wear out quickly. Use test and measurement tools to do a more in-depth evaluation of your tracks. Ultrasonic testing can detect cracks in a track link, as well as the loss of material on the inside of a link, indicating problems if the track pin starts to exhibit excessive play.

By following these maintenance practices you can greatly extend the life of your undercarriage and reduce the chance of costly repairs. Periodically checking your undercarriage will help your undercarriage last longer, perform better, and keep the machine safe. It will also keep machines from sitting for an extended period. And, it will prevent downtime, saving you time and money.

Conclusion

The undercarriage is absolutely one of the most crucial parts of your excavator, and if you neglect it, you’ll absolutely pay for it in terms of expensive repairs and long downtime. By understanding how to identify problems with the undercarriage components, inspecting them regularly, and using diagnostic tools, you can keep your excavator in tip-top shape.

Detecting and knowing about a problem lets you act quickly and effectively to prevent further damage and keep your machine working well. Whether you’re a seasoned operator or you’re just starting out in the construction industry, these tips will help you keep your excavator in top shape and save repair dollars. The bottom line is that a well-maintained undercarriage saves you money and performs much better.

Follow us on :YouTube.