Table of Contents

ToggleWhat types of excavators are there?

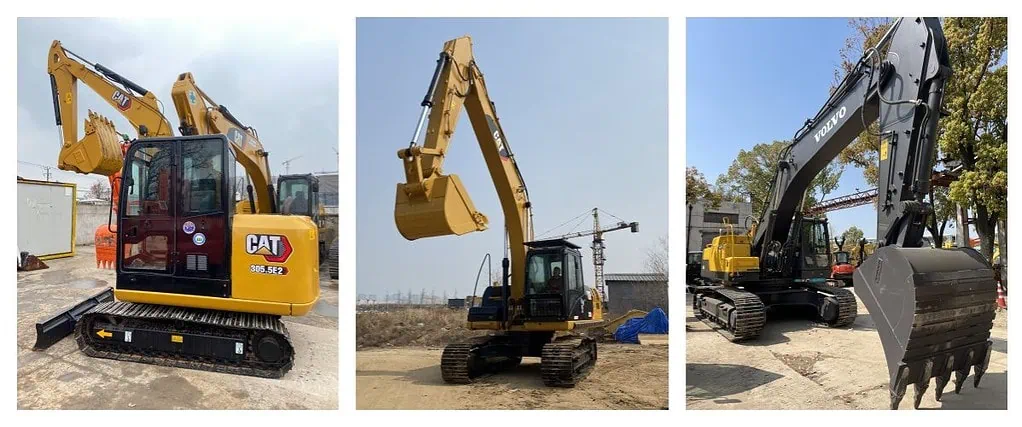

Classified by size

Small excavator

- The overall machine weight is generally between several tons and a dozen tons.

- Suitable for small-scale engineering operations such as courtyard renovation, pipeline laying, and small-scale farmland water conservancy construction. It has the characteristics of being flexible and small, and being convenient for operation in narrow spaces.

Medium excavator

- The overall machine weight is usually between a dozen tons and thirty-some tons.

- Widely used in general building construction, road construction, municipal engineering, etc. It has high operating efficiency and can adapt to more complex working conditions.

Large excavator

- The overall machine weight is mostly more than thirty tons.

- Mainly used in large-scale mining and large-scale earthwork projects. It has strong digging force, wide operating range, and high production efficiency.

Classified by transmission method

Hydraulic excavator

- ransmits power through the hydraulic system to realize actions such as digging, slewing, and traveling.

- It has the advantages of flexible operation, smooth movement, and being able to achieve stepless speed regulation. It is currently the most widely used type of excavator in the market.

Mechanical excavator

- Uses mechanical transmission devices to drive the working device to perform operations.

- The structure is relatively simple, but the operation is relatively complex. The working efficiency and flexibility are generally lower than those of hydraulic excavators. Currently, it accounts for a relatively small proportion in the market.

Classified by walking mode

Crawler excavator

- Walks by relying on crawlers. It has low ground pressure and strong trafficability and can adapt to various harsh working sites.

- Commonly used in mines, large construction sites and other places with complex operating environments.

Wheeled excavator

- Adopts tires for walking and has good mobility and fast transfer speed.

- Suitable for urban construction, road maintenance and other projects that require frequent transfers.

Classified by working device

Face shovel excavator

- Its working device is mainly a face shovel and is suitable for excavating materials above the stop surface.

- Generally used in large-scale earthwork projects and mining.

Backhoe excavator

- The working device is a backhoe and is mainly used for excavating materials below the stop surface.

- It is the most common type of excavator and is widely used in various construction projects and municipal engineering.

Dragline excavator

- The working device is a dragline. It operates by pulling the bucket with a wire rope.

- Suitable for excavating deeper trenches and underwater operations.

Grab excavator

- The working device is a grab and is mainly used for loading and unloading bulk materials and grabbing materials.

- Commonly seen in ports, docks and other places.

What types of excavators are there?

What precautions should be taken when operating different types of excavators?

Small excavators

Assessment of the operating environment:

- Due to the small size of small excavators, when operating in a narrow space, carefully assess the operating environment to ensure there is enough operating space and avoid colliding with surrounding objects.

- Check the ground bearing capacity of the operating site to prevent the excavator from sinking due to soft ground.

Control of operation accuracy:

- The operation accuracy requirements of small excavators are relatively high. Especially when performing fine operations such as garden construction and indoor demolition, operate the control levers slowly and accurately to avoid excessive force causing damage.

- Pay attention to the movement amplitude of the bucket to prevent hitting surrounding buildings, pipelines and other facilities.

Safety protection:

- Operators should correctly wear seat belts and safety helmets to ensure their own safety.

- During the operation process, always pay attention to the surrounding people and set up obvious warning signs to prevent others from approaching.

Medium-sized excavators

Stability:

- Medium-sized excavators are relatively heavy. Before operation, ensure that the machine is parked stably, and the outriggers are fully extended and firmly supported on the ground.

- Avoid large-scale slewing and excavation actions on slopes to prevent the machine from overturning.

Load control:

- According to different operation tasks and soil conditions, reasonably control the excavation depth and bucket capacity to avoid overloading operations and damage to mechanical parts.

- Pay attention to the pressure indication of the hydraulic system. When the pressure is too high, stop the operation immediately and check the cause.

Maintenance:

- Regularly perform maintenance on medium-sized excavators and check the operating conditions of key components such as the engine, hydraulic system, and transmission system.

- Keep the machine clean and promptly clean dust and debris on parts such as radiators and air filters to prevent overheating and clogging.

Large excavators

Professional training:

- Operating large excavators requires professional training to be familiar with the machine’s performance, operation methods, and safety regulations.

- Operators should have rich experience and skills to be able to deal with various complex operating situations.

Team collaboration:

- In large-scale projects, multiple devices usually need to work together. Operators should closely cooperate with other personnel, follow commands, and ensure construction safety and efficiency.

- Maintain good communication with on-site engineers, safety officers, etc., and promptly understand construction requirements and safety precautions.

Safety inspection:

- Before each operation, conduct a comprehensive safety inspection of large excavators, including mechanical structures, electrical systems, braking systems, etc.

- Check the integrity of lifting equipment such as wire ropes and hooks to ensure the safety of lifting operations.

- In short, different types of excavators should strictly abide by safety regulations during operation, operate correctly according to the characteristics and operation requirements of the machine, and perform regular maintenance to ensure the normal operation of the equipment and the safety of operators.