Excavators are the main force in the construction and mining industries. The digging capacity of excavators determines the progress of your construction period and the total production volume. Then, how to select an excavator that can run continuously for hundreds of hours without any malfunctions? The following are the important factors that you need to consider, so that the excavator you choose can achieve the best performance in all digging scenarios.

El excavator digging is not just about the depth or width of the excavation; it involves a combination of factors such as machine stability, fuel efficiency, operator comfort, and durability. Choosing the right excavador digging for the job can enhance work efficiency, reduce downtime, and lower long-term operational costs. A well-chosen machine ensures that the job gets done efficiently, on time, and with fewer mechanical issues.

To fully understand the steps and improve your digging performance, let’s dive deep into all the aspects that affect how an excavator operates.

Tabla de contenido

PalancaWhat is the Basic Working Principle of an Excavator?

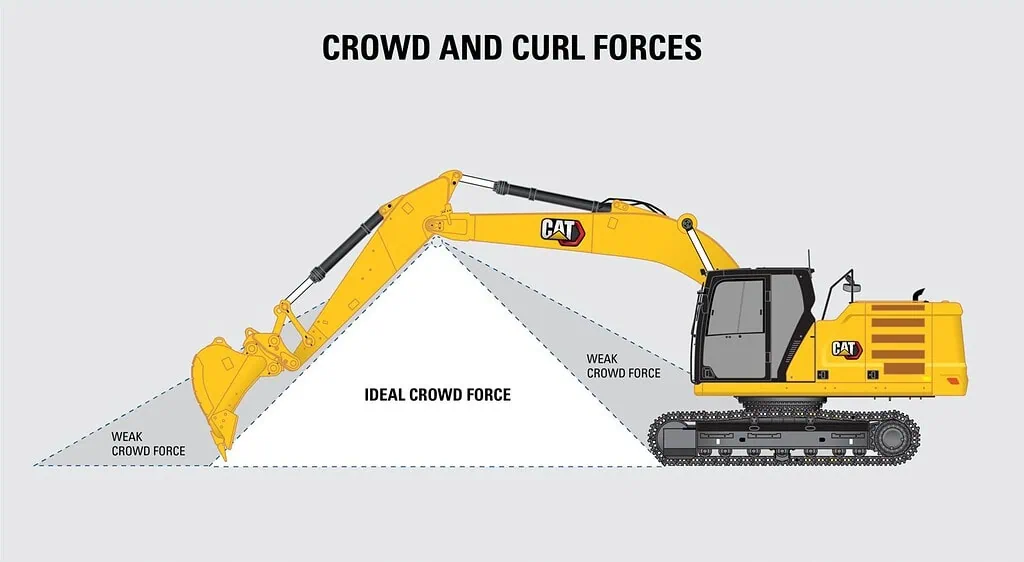

Let’s be honest. An excavator is a hydraulic machine. In other words, their operation is powered by pressurized hydraulic fluid. The major part such as the boom, arm, bucket, and tracks are controlled by a system of hydraulic cylinders that move in response to fluid pressure. So, how does it all work? Well, let me break it down for you.

Hydraulic Pumps

The engine powers the hydraulic pump. This is what sends the pressurized fluid to the cylinders. Boom and Arm Movements: These are controlled by hydraulic cylinders. The boom lifts the arm, while the arm digs into the earth or lifts material from the ground.

Bucket Functionality

The bucket is the tool that does the work. Controlled by hydraulic power, this attachment can rotate, tilt, and grab materials. The tool versatility, combined with the available power, makes things like excavator digging, trenching, grading, and lifting topsoil, boulders, trees, or whatever else you can think of possible.

Excavators are engineered to dig more efficiently than any other machine or vehicle. The marriage of high pressure hydraulic power and mechanical leverage creates the fastest and most powerful way to remove soil/mud, sand, or anything else from point A to point B. The exactness of this movement is why an excavator digging is the ideal tool for heavy duty on a construction site.

Expanded Insights

Excavators can come in different sizes and configurations, and an expensive excavator can come with various bucket and attachments. For example, you can take off the excavator digging bucket and put on a rock bucket , or let’s say you can even attach a hydraulic hammer for breaking rock. Additionally, the entire upper structure of the machine, which is also called the turntable, can rotate freely 360 degrees, allowing you to dig in any direction without having to move the entire excavator digging.

What Are the Key Components of an Excavator?

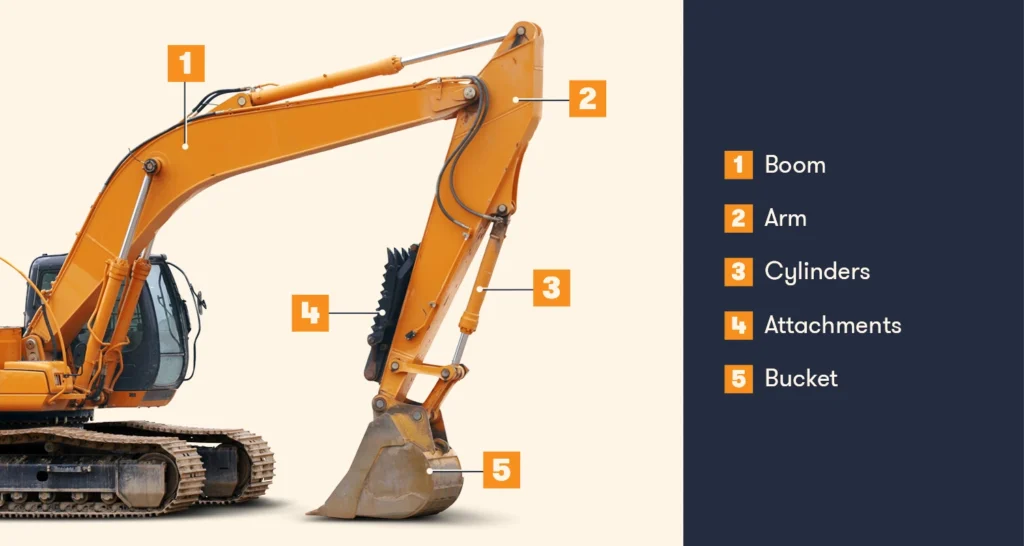

The performance of an excavator depends on its core components, which must work in unison to ensure efficient digging and material handling. Each part plays a crucial role:

Boom: The long arm that extends outward from the machine’s main body. It can be adjusted to reach various depths and angles for digging.

Arm : Attached to the boom, the arm further extends the reach of the bucket. It is critical for providing the extra length necessary for deep excavations.

Bucket: The primary tool for digging. The size, shape, and strength of the bucket are key considerations based on the type of materials being handled.

Hydraulic System: The heart of the excavator. It consists of hydraulic pumps, valves, and cylinders that drive the machine’s movements. Hydraulic systems are essential for the speed and precision of the machine’s operations.

Engine: Powers the hydraulic system and the machine’s movement. High-performance engines enable excavators to work efficiently under heavy loads for extended periods.

Undercarriage: The track or wheels that provide mobility. The undercarriage must be durable to handle rough terrain and carry the weight of the excavator, especially during digging.

Operator’s Cabin: Designed for comfort and safety, the operator’s cabin houses the controls that manage all the movements. Comfort features, like air conditioning and ergonomically designed seats, help increase operator efficiency and reduce fatigue.

Expanded Insights:

The hydraulic system is one of the most important features for the machine’s performance. Advanced systems now include load-sensing hydraulics, which adjust the flow of hydraulic fluid based on the pressure and load, thus improving fuel efficiency. The undercarriage comes in two main types: rubber tracks, which are ideal for smooth surfaces, and steel tracks, which provide better traction on rough, uneven ground.

What Factors Should Be Considered When Choosing an Excavator?

Loading and Lifting: A machine’s stability and load capacity will determine if you can lift heavy loads and equipment like rocks, concrete, or debris. If you need to lift heavy objects or work with cranes and hoists, choose a model that can handle the loads you plan to use it for.

Size and Width: Size is important, too. The size of your excavator, especially its width, will determine if it can fit into and work within confined areas. Compact excavators, for instance, provide better maneuverability and access to job sites in tight areas, making them ideal for work in urban areas or environments where space is limited.

Transportation and Mobility: Getting the excavator to where you are working can be a challenge and expensive if you end up with an excavator digging is too big, too heavy, or hard to move. Some models are made to be very mobile and easy to transport. Examples include machines you can load onto a regular construction trailer and tow, or those you can transport as a regular truck-sized load.

Ground and Surface Conditions: Not all excavators can work in all types of ground or surfaces. Things that affect how an excavator will work in certain ground conditions include tracks versus tires, rubber versus steel tracks, and ground pressure. Whether you need to work on soft ground, mud, or sand, or on hard, rocky surfaces, these are considerations you should take into account.

Versatility: Your excavator digging should be able to use a variety of attachments (like hydraulic hammers, augers, or grabs) to help you do different types of work. If the machine has a quick-change system, you can easily switch from one type of work to another, making you more productive on a variety of projects.

Environmental Conditions: Machines designed to work in high-temperature environments or dusty conditions will be more efficient and last longer. If you work in a particularly harsh environment, you may need to invest in a machine that has extra filters or improved cooling systems for continuous performance.

After-Sales Support and Warranty: Always check the warranty and after-sales support options for the manufacturer. Some brands offer extended warranties or service packages that can save you a lot of money on future repairs.

How to Improve Excavator Digging Efficiency?

Efficient excavator digging is critical to minimizing downtime and maximizing productivity. Here are more detailed strategies for improving the efficiency of your excavator.

Operator Training

A skilled operator is critical for getting the most out of your machine. Training should emphasize more than just how to operate the machine, focusing also on avoiding unnecessary movements and using best practices to optimize digging cycles. Proper techniques like shovel cutting or proper bucket positioning can make a huge difference in fuel burn and machine wear.

Hydraulic System Maintenance

Make sure your hydraulic fluid is changed on time and there are no leaks in your hydraulic system. A poorly performing hydraulic system will sap power from your machine and slow down your excavator digging. If you’re experiencing breakdowns or system problems, check your filters regularly to make sure they’re not getting clogged up as well.

Use the Right Attachments

Different buckets and tools are designed for specific types of work. A clamshell bucket is perfect for lifting material out of a deep trench, but a grapple bucket is better for handling rocks or debris.

Plan the excavator Digging Path

How you plan to dig will help you to be more efficient. For instance, making sure the operator has a nice, smooth path to follow can save you the time and effort of constantly repositioning the machine, saving time and fuel.

What Are the Common Excavator Failures and How to Avoid Them?

Worn or Broken Bucket Teeth

Constant excavator digging and heavy loads can cause the bucket teeth to wear out or break. Regularly inspecting the bucket teeth and replacing them when worn is the best way to prevent this issue.

Track Problems

Excavators rely on their tracks to move around, so any problems with the tracks can severely impact their performance. Inspect the tracks regularly for wear and tear, and replace them as needed to avoid any issues.

Electrical System Failures

Issues with the electrical system, such as dead batteries or faulty wiring, can cause the excavator digging to lose power or fail to start. Regularly check the electrical system and replace any worn or damaged components to prevent these types of failures.

The steel grouser tracks, especially, tend to wear out over time, especially in abrasive environments. Keep an eye on your tracks and replace them as needed. Also watch the undercarriage for wear, as it can affect the overall stability and movement of the excavator digging.

How Do Excavators Perform in Different Working Environments?

Excavator digging need to be versatile and capable of working in various types of environments. Here’s what that looks like in practice:

Soft Soil

For swampy, mud, or soft soils, an excavator digging with wider, heavy tracks will provide better flotation. The wider the track, the more surface area the weight of the machine gets distributed across, meaning it’s less likely to bog down and get stuck.

Rocky Terrain

If you’re digging in rocky soil, look for an excavator digging with reinforced, high-strength steel tracks that won’t get damaged, and a heavy-duty bucket. You can also attach a hydraulic hammer to the machine to break rocks if needed.

Working in Confined Areas

For tight spaces, you need a smaller, more compact excavator digging. These machines are more nimble and can move around in areas where a larger machine can’t. Look at mini-excavators and smaller machines that have a smaller footprint. Attachments can make a big difference in these situations, and mini-excavators can also perform smaller excavation tasks in urban or small construction sites.

How Does Excavator Size Impact Performance and Cost?

Size matters because a lot of times it reduces the cost to operate and maintain that machine. You have to have the right machine for the job. You don’t want to spend more money maintaining a big machine that’s not being used when a smaller machine can do the job just as well. This will maintain both the larger and smaller machine better for the jobs they were designed for. Let’s get into why size matters.

Small Excavators

Small excavador are more cost-effective for getting the job done. People use compact excavators in tight places, in the dirt, in a hole, in a trench. Typically, they’re mini-excavators, the smallest possible size. They are lightweight, easy to transport, and more cost-effective than larger machines for digging. Their excavator digging depth is less. Their digging capacity is less. Their breakout capacity is less than a big machine.

But we use them for a lot of small, tight places. For example, small machines work great across the street in a retail center. They’re great on jobsites where you can’t get the big machines into the backyard. Use these machines in dense urban areas for construction, landscaping. You can use a little machine for light trenching in an urban area.

Compact Excavators

Also known as mini excavator digging, compact excavators are small, lightweight machines that can be easily transported to job sites. They are commonly used in residential construction, landscaping, and utility work. Compact excavators are versatile and can be equipped with various attachments, such as augers, breakers, and buckets, to perform a wide range of tasks in tight spaces.

Long Reach Excavators

These excavators have an extended arm and boom, allowing them to reach farther and dig deeper than standard models. They are often used for dredging, deep trenching, or demolition work where extended reach is necessary. Long reach excavator digging are more specialized and not typically used for general construction or earthmoving projects.

When selecting the size of an excavator, consider the working area and the ability to maneuver. Tight spaces or areas with obstacles may require a smaller excavator digging to ensure you can get the job done. Additionally, your work area may impact the type of undercarriage you need and whether you use a dozer blade.

How to Optimize Excavator Fuel Efficiency?

Fuel consumption is one of the largest operating expenses for excavator digging, so increasing fuel efficiency will save you money without costing you productivity. Here are several things to consider when trying to improve the fuel efficiency of your excavator digging:

Size the Machine Properly

Are you using the right size machine for the job? If you are, everything will be much more efficient. Using a machine that is too large just to have it on the job will cost you in fuel and increased operating expenses. Using a machine that is too small for the task will work the engine harder, burning more fuel, and wearing out the machine quicker.

Regular Maintenance

The machine’s engine, hydraulics, and filters all need to be as clean as possible to operate most efficiently. You need to change the oil regularly, replace air filters, and keep the hydraulic fluid topped off and flowing well to make everything else operate efficiently. All of this will also help with fuel efficiency.

Eco Mode

Many brand-new excavators come with an “Eco Mode” that can adjust the engine speed and hydraulic power when working in certain conditions or with less power. This can lead to significant fuel savings. Make sure your operators are aware of this feature and have it turned on when it makes sense. For many operators, eco mode is a turn the button on when nothing is happening, then turn it off when digging mode. But in the right situation, save yourself a little bit of fuel and turn on that eco mode.

Operator Training

Operators need to be trained for fuel-efficient operation. Identify techniques such as not making excess movements, not overworking or overdriving the machine, and using smooth operation to save time and fuel.

Manufacturer publications and sales materials will discuss upcoming equipment that’s hitting the construction market. Manufacturers have prototyped all-electric excavators as well as hybrid machines using electric power part of the time and an engine part of the time.

Resumen

Excavator digging is the key to all construction and excavation work; it is the fastest and most efficient way to move large volumes of earth. From understanding the basic principle of how they work to what type of machine to use, how to maintain a good cycle time and adapt the machine to different conditions, they are an essential part of any construction site. If you can maximize your efficiency, minimize your downtime, and make sure your machines are well maintained, you will be able to be part of successful, profitable projects that are completed on time and on budget.For more information or professional advice, feel free to contact us.