Is everything running perfectly on your excavator? Well, if it isn’t, you know why: poor maintenance, which means expensive breakdowns and unscheduled downtime. Learn how a well-thought-out excavator maintenance schedule can extend the life of your machine, reduce downtime, and avoid costly repairs. That is, if you care to learn.

A regular excavator maintenance schedule is crucial to keep your machine performing at its peak. From improving fuel efficiency to enhancing safety, routine checks and timely repairs prevent unnecessary breakdowns. Whether you’re using your excavator for construction, mining, or other heavy-duty tasks, maintaining it regularly can save you from expensive repairs and reduce operational costs. Learn the essential maintenance practices and recommended schedules to keep your excavator in top condition, extend its service life, and avoid delays in your projects.

Let’s go deeper into this concept of a maintenance schedule, and how it can benefit your excavator and bottom line. Keep scrolling!

Table of Contents

ToggleWhy is Regular Excavator Maintenance Crucial?

An excavator is a valuable piece of equipment. Its performance can make or break your construction projects. Regular maintenance keeps your excavator running at its best. It extends its life, increases efficiency, and prevents unscheduled downtime and expensive repairs. Excavators work in harsh conditions and will wear out if not properly maintained. A maintenance schedule will point out the minor things before they become major, costly ones.

Key Benefits of Regular Excavator Maintenance

Increased Efficiency

Without a correctly maintained machine, critical components like filters, oil systems, and hydraulics fail, sabotaging fuel efficiency and causing higher operational costs. A machine operating at peak efficiency burns less fuel per hour, digs faster, and lifts more.

Prolonged Lifespan

Regular maintenance, such as routine oil changes, checking the engine, and inspecting hydraulic components, removes the stress from these critical systems. A proactive approach like this keeps these components from failing and extends the life of the machine. A well-maintained excavator has a higher resale value when you’re ready to trade in or sell.

Reduced Downtime

By taking care of things and catching problems early, the machine is less likely to have a catastrophic failure, allowing it to run day in and day out without downtime. Every day your machine isn’t running is a day you’re not an excavator operator; you’re a parts changer and out of work.

Enhanced Safety

When you take care of your equipment with regular maintenance, all the safety features will function like the hydraulic pressure, braking systems, alarms, and everything the manufacturer designed to protect the operator and everyone else on the job site.

Prevention of Expensive Repairs

You’re less likely to have a small problem turn into a huge issue the better you maintain your machine regularly. For example, when you see a part getting worn down, replace it before it fails! That’s thousands of dollars in repair you just saved, and your machine is still in good working order.

The Role of an Excavator Maintenance Schedule

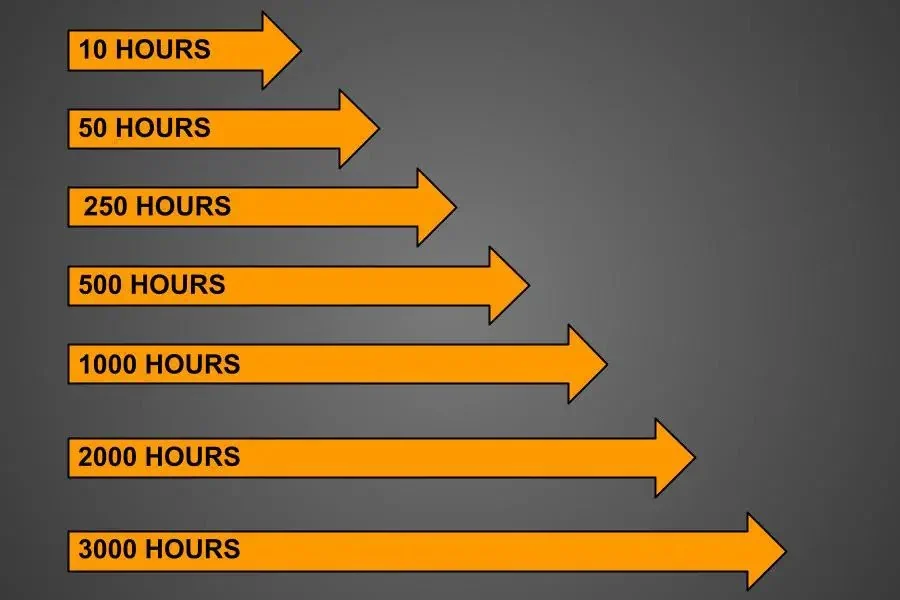

An excavator maintenance schedule is where you make sure you service every part of the machine right when it needs it, like every 250 hours, 500 hours, etc. By doing this, you keep it running like new, save expensive repairs, and avoid downtime. Adjust as needed for your conditions and how you use the machine. Inspect the machine, and keep records so you can catch things before they become major failures.

What Factors Affect the Frequency of Excavator Maintenance?

The frequency of maintenance on your excavator depends, based on how many hours a day you use it, under what conditions you use it, and how hard you use it.

Operating Hours

The frequency at which service is scheduled is one of the primary factors for when to schedule maintenance. Components wear out with time, so knowing how many hours the machine has been used allows you to keep up with when it should receive maintenance. For example, after 250 operating hours, the hydraulic system needs to be greased and the filters need to be checked.

Environmental Conditions

If your excavator has been in severe environments, like a construction site where it may be noticeably dusty or muddy, your maintenance needs will increase. For example, it may need air filters more frequently, and you need to check the hydraulic fluid level more often. This helps keep everything running normally and prevents components from being affected by external contaminants.

Intensity of Usage

Another factor is how hard you use the machine. If it’s used for severe-duty applications, or you’ve got people operating it constantly, you will have more wear and tear than something that’s lightly used. If you’re working it hard, you have to check more often or else things might break, and when they do, they cost you a lot more.

Excavator Maintenance Schedule Based on Usage and Environment

| Factor | Frequency of Maintenance | Recommended Action |

| Light Duty Usage | Every 500–1000 hours | General checkups, oil and filter changes, and undercarriage inspections. |

| Heavy Duty Usage | Every 250–500 hours | Additional checks for hydraulic systems, engine components, and frequent filter replacements. |

| Harsh Environment (dusty, wet) | Every 100–250 hours | Increased filter changes, more frequent fluid checks, and air intake inspections. |

What Should Be Included in a Standard Excavator Maintenance Schedule?

A standard excavator maintenance schedule includes regular checks and services designed to keep the excavator running efficiently. Below is a general breakdown of what you should include in your maintenance plan.

Daily Inspections

Daily checks are essential to ensure the excavator is ready for work and to catch minor issues before they turn into major problems. Some daily maintenance tasks include:

- Fuel filters: Replace fuel filters as required.

- Belts and pulleys: Inspect and replace drive belts or pulleys as necessary.

- Lubrication: Ensure that all moving parts are properly lubricated.

Every 250 Hours

At this point, you should perform some more in-depth checks.

- Oil Change: Regular oil changes prevent wear and tear on the engine and keep the machine running smoothly.

- Check the hydraulic system: Make sure there are no apparent leaks and that the pressure in the hydraulic system is where it should be.

- Filter Replacement: Changing oil and fuel filters will prevent your fluids from becoming contaminated and will generally help your machine perform better.

Every 500 Hours

This is when you will want to inspect the undercarriage and more internal components of the excavator. Here, some of the things you should be regularly checking include:

- Track Inspections: Ensure the tracks are tensioned properly and check the tracks for damage.

- Leak Checks: Look over every single hydraulic and engine component on the machine for leaks.

- Undercarriage Inspection: Again, you will want to clean the undercarriage out the best you can and inspect it for wear and damage.

Every 1000 Hours

At this point you’ll want to do a full inspection. This includes:

- Engine System: Check the engine out thoroughly. This is the lifeblood of your machine, and a problem here can cause an enormous bill.

- Transmission and Hydraulic Systems: Make sure everything is working correctly here, with no unusual wear and no drips or leaks.

- Component Check: You should check all the major components of the machine now, if you haven’t already. Rotation system, tracks, bucket.csrfYou must complete monthly procedures as well. Keep a record of your work so you can anticipate future maintenance needs and identify changes over time.

Should I Follow the Manufacturer’s Recommendations for Maintenance?

While a general maintenance schedule is a good place to start, you should always follow the manufacturer’s recommendation for maintenance. This schedule is unique to your make and model of excavator. The manufacturer’s schedule is designed specifically for the piece of equipment you own. It takes into account engine specifics, hydraulic systems, and how hard the machine is supposed to work. The manufacturer’s schedule is the exact maintenance you should perform if you want your machine to last.

However, reality will dictate changes. If you work in a harsh environment with your excavator or it works harder than it was designed to daily, you may need to perform more frequent maintenance than the standard schedule offers. For example, a machine that works in muddy or rocky terrains might be subject to faster wear on certain parts than a machine that works on sandy soil.

If that’s the case, you might need to inspect those parts more frequently. You might need to change oil more often because the conditions break the oil down sooner than normal. These are scenarios where adapting the maintenance schedule to how you’re using the machine will help the machine last longer, operate better, and provide more value.

How Can I Identify When My Excavator Needs Immediate Maintenance?

Even with a solid maintenance schedule, it’s important to be vigilant for signs that your excavator needs immediate attention. Early detection can prevent costly repairs and prevent downtime. Here are some warning signs to watch for:

- Unusual Noises: Grinding, clanking, or squealing sounds often indicate problems within the engine, hydraulics, or undercarriage/tracks. These signs should not be ignored, as they can indicate severe damage.

- Decreased Performance: Noticeable loss of power, sluggish operation, or a decrease in lifting capacity can indicate a major component failure. Loss of hydraulic pressure, fuel system trouble, or engine malfunction can cause these symptoms.

- Overheating: Repeated overheating, particularly if the excavator shuts down or activates safety features, can cause long-term damage to the engine. Regular checks of the temperature gauge and coolant levels can identify the problem before it becomes a serious issue.

- Leaks: Always turn off the machine and locate the source of the leak if you see any type of fluid dripping or spraying from the machine. Coolant, hydraulic oil, engine oil, and fuel must be contained, cleaned up, and repaired immediately. Any leak is big trouble.

- Unsafe Operation: Equipment that fails to operate smoothly and in a controlled fashion poses a serious safety risk.

- Anything Unusual: When you are in the field using your equipment, and you notice anything out of place, whether something is heard, seen, or smells different, pay attention. Don’t ignore things.

If any of these symptoms arise, adjust your maintenance schedule or have the machine inspected immediately to avoid further damage.

What Are the Benefits of Sticking to an Excavator Maintenance Schedule?

Adhering to a strict excavator maintenance schedule offers several key benefits that not only improve the machine’s performance but also save money and extend its working life:

- Reduced Downtime: If you maintain your equipment, the overall likelihood of those unexpected breakdowns is much less. Preventive maintenance means a machine that’s going to keep running properly, enabling you to work steadily, and completing jobs in a timely fashion.

- Cost Savings: Regular maintenance inspections are going to nip small issues in the bud before they become costly repairs. It’s much cheaper to have your regular services on filters, fluids, belts, teeth, etc., than it is to replace the whole machine. The money you save trying to put off a simple maintenance cycle is peanuts compared to what you’ll eventually spend when your machine runs less and fails.

- Higher Resale Value: Machines with a full maintenance record, so you know everything was done like it was supposed to be, have a higher value than a machine with no maintenance history. You’re always going to make more money on something that’s been well taken care of over the years than something that hasn’t.

By adhering to a maintenance schedule, you’re not just prolonging the life of your excavator—you’re also protecting your investment and reducing your overall operating costs.

How Do I Create My Own Excavator Maintenance Schedule?

Creating a maintenance schedule for your excavator is a simple yet effective way to monitor the health of your machine. Start by noting the suggested intervals from the manufacturer for changing the oil, filters, and other critical checks. Once you have the basic schedule, think about your machine’s usage and adjust the schedule based on how it’s being used and the environment it’s used in.

For example, if your excavator is running 12 hours a day in demanding conditions, you might need to cut back on the recommended service intervals. So, the number of hours your excavator runs is key to keeping up with the basics. Using something like a maintenance app, a spreadsheet, or even a written log to designate hours and remind you of regular intervals will work wonders.

One of the hands-down coolest things about having an in-depth maintenance log is when it comes time to sell the machine. A buyer who wants a well-maintained machine with everything recorded and documented will find immense value in those printed and logged records, and it could add a lot of money to the sale price.

What Are the Most Common Myths About Excavator Maintenance?

There are a number of myths or misconceptions about excavator and heavy equipment maintenance that lead to improper care. Let’s debunk a few myths:

Myth 1: Older Excavators Don’t Need As Much Maintenance: False. Whether an excavator is nearly new or 20 years old, it requires consistent checks and services to remain operational. Old machines wear out, but everything still has to work to keep the machine running.

Myth 2: If the Excavator is Working Fine, No Maintenance is Needed: Just because the engine starts and the machine swings, booms, and digs doesn’t mean all is good. Ancillary systems and components can be broken or failing while still allowing the machine to operate. Preventative maintenance can help catch issues before they affect performance.

Myth 3: It’s Okay to Delay Changing Filters: Another fairytale. Filters protect the engine and hydraulic systems from life’s garbage. Delaying changing filters lets dirt or contaminants build up, which leads to lost machine performance and expensive repairs.

Pay attention to those myths and make sure you’re not buying into anything that isn’t true that could sabotage the life and reliability of your excavator.

How Does an Excavator Maintenance Schedule Impact Resale Value?

Equipment Resale Value: A well-maintained excavator always commands a higher resale value than a machine with no documented maintenance. When buyers see proof the excavator has been serviced on time and is in excellent shape, they can trust it should be a reliable purchase. The ability to see a maintenance schedule adds a level of credibility, which shows the excavator has been taken care of since new.

Resale value can be affected by many different things, but the one thing you have control over is your maintenance record. A complete and up-to-date record of your maintenance is just like money in the bank when it’s time to sell. People will pay a premium for a machine they know they can rely on. Again, that’s how a disciplined maintenance routine can pay for itself several times over!

What Tools and Equipment Should I Use for Excavator Maintenance?

The right tools are essential to completing excavator maintenance correctly. Whether you’re performing basic checks or a complete service, these tools will make the job easier and more effective:

- Hydraulic Pressure Tester: If you can’t check the hydraulic pressures by hooking up a gauge and reading the numbers, you can’t tell if anything is working right! Torque Wrench: Keeping bolts and other fasteners tightened to the manufacturer’s specifications can mean the difference between a trouble-free operation and component failure from loose parts.

- Oil Filtration System: Make oil changes simple to keep the engine and hydraulic systems operating at peak performance.

- Track Tensioning Equipment: Maintenance for proper track tension is required to maintain track life and make sure you don’t throw a track off and damage something.

Conclusion

A regular maintenance schedule is critical to the longevity, performance, and reliability of your excavator. Whether you’re a seasoned operator or a first-time owner, understanding how often you need to perform maintenance and what types of maintenance tasks you need to tackle will help you keep your machine in peak condition.

So start your excavator maintenance schedule today and keep your excavator running in top shape for years to come.